Military Packaging Supplies Milspec packing Materials

Milspec military specification materials films bags and containers

Big Valley Military packaging supplier source for mil spec packing materials for military applications and requirements.

GSA government procurement and government contractors contact us for pricing or send solicitations via Fax (720) 306-2484

Barrier films, custom made bags, inner foam cushioning, shipping containers boxes, and static protection products. Military packaging containers made from wood, corrugated, and plastic. Military packaging foil bags. Milspec bagging Mil-B-131, Mil-B-121 Mil-B-81705

Military mil spec polyurethane foam sheets

Military spec fiberboard boxes

Military milspec foil barrier bags bagging

Milspec packaging materials, mil spec tapes, strapping, stretch film, and military specification labels. Cushioning materials from foam to bubble in different thicknesses and sizes. These cushioning materials can be the primary components of bags and pouches or a supporting component of more complex packaging designs. Below is a list of some of the more frequently requested cushioning materials.

Military specification foams

Foam Polyethelyne PPP-C-1752 A-A-59135 A-A-59136

Foam-Airless Bubble PPP-C-1842B A-A-3129

Rubberized Horse Hair Bound Fiber PPP-C-1120 PPP-C-1120

Bubble Wrap PPP-C-795 PPP-C-795

Polyurethane Foam MIL-P-26514 MIL-PRF-26514

Foam (Pink or White; 1/32″, 1/16″, 3/32″)

Air Bubble (Pink Anti-Stat or Clear; 3/16″, 5/16″ 1/2″)

3rd Webb (Tri-layer poly/bubble/poly; 3/16″, 5/16″)

Flexshield (2-layer static shield/pink anti-stat bubble)

Foil Laminate (Tri-layer foil/bubble/poly)

Cancel (static free or ESD shield capabilities designed specifically for the electronics industry)

Mil Spec Barrier Bags, Sheets, Roll Stock

First choice for packaging that meets military specifications. Our proven experience together with qualified producers material suppliers ensures yoru success. We understand the specifications, the materials, and the market.

MIL PRF 121 Grade A

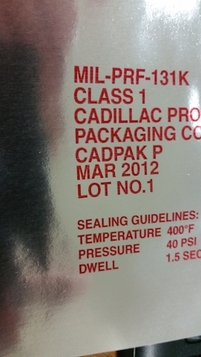

MIL PRF 131 CLASS 1

MIL PRF 131 CLASS II

MIL PRF 131 CLASS III

MIL PRF 81705 TYPE 1

MIL PRF 22191 TYPE 1

MIL PRF 22191 TYPE 2

MIL PRF 121 GRADE C

FilmsCharacteristics/Properties

Static Shield Polyester/metallic/anti-static PE, transparent

Moisture protection, vapor proofEMI Static Shield/REV C Moisture protection, vapor proof, radio frequency

and magnetic field resistance.

MIL-B-131 III Type 1 Kraft Foil Kraft paper and foil laminate.

MIL-B-121 G Kraft Poly Kraft paper and PE laminate Tyvek Foil Static protection, moisture protection NAPP Foil Poly/foil/poly.

MIL-B-131 lower cost alternative Mylar Foil Light resistance, printable material.

NATURAL KRAFT POLYETHYLENE COATED BAGS & ROLL STOCK

Polypropylene film, polyethylene foil, nylon film, tyvek™, Aluminum Foil Natural Kraft Laminate, Aluminum Foil, Polyethylene Cotton Scrim, Metalized Tyvek™, Rev B Metalized Tyvek™, Rev C Metalized Polyester, Metallized Films Polyester, Polyethylene, Aclar, Polyester, Polyethylene Coated, Scrim, Microwax (1 or 2 sides)

All Military Packaging Supplies Milspec Packing Materials

A-A-1051

A-A-1898

A-A-203

A-A-3174

A-A-59135

A-A-59136

A-A-883

ASTM-D-5118

ASTM-D-5330

ASTM-D-5486

ASTM-D-5749

ASTM-D-6123

ASTM-D-6251

ASTM-D-6256

ASTM-D-6880

ASTM-D-7478

MIL-B-117

MIL-B-121F

MIL-B-131

MIL-B-22191

MIL-B-26195MIL-C-104

MIL-C-11796

MIL-C-15074

MIL-C-6529

MIL-D-3464

MIL-D-6054

MIL-DTL-117

MIL-DTL-17667

MIL-DTL-24466

MIL-DTL-46506

MIL-DTL-81997

MIL-G-23827

MIL-P-130

MIL-P-17667

MIL-P-3420

MIL-PRF-121G

MIL-PRF-131

MIL-PRF-16173

MIL-PRF-21260

MIL-PRF-22191

MIL-PRF-23827

MIL-PRF-26514

MIL-PRF-3150

MIL-PRF-32033

MIL-PRF-3420

MIL-PRF-46170

MIL-PRF-7808

MIL-PRF-7870

MIL-PRF-81322

MIL-PRF-81705

MS20003

MS27683

MS27684

MX56789

MXC56789

NN-P-71

PPP-B-1672

PPP-B-566

PPP-B-601

PPP-B-621

PPP-B-636

PPP-C-1120

PPP-C-1752

PPP-C-1797

PPP-C-795

PPP-P-291

PPP-T-45

PPP-T-60

PPP-T-76

PPP-T-97

VV-L-800

Mil-PRF-131J Flexible Moisture Barrier Material

The barrier materials covered by this specification are intended for use in specialized military methods of preservation. The combination of all performance characteristics of MIL-PRF-131; seam strength and fabrication; water vapor transmission rate; breaking strength; puncture, blocking and curl resistance; contact corrosivity; delamination; and water resistance of markings provide the necessary requirements for protection from exposure to the extremes of the navy/naval aviation environment. Navy/naval aviation items are exposed to high moisture, high salt concentration, transfer at sea, rough handling, and minimal storage conditions. There are no commercial equivalents that meet the physical, mechanical and corrosion requirements necessary to protect material that is exposed to the operational naval aviation environment.

Specifically, Methods 41, 42, 43, 51, 52, and 53 of MIL-STD-2073-1C use MIL-PRF-131 as the premier source of barrier materials that provide water vapor proof (and water vapor proof with desiccant) protection for applicable items encountering the above conditions. MIL-PRF-131 provides the building blocks for applying specialized military preservation techniques approved under MIL-STD-2073-1C.

Class 1 use. Class 1 material with plastic non-woven backing is intended to be used in all packaging applications where heat-sealable, water vapor proof, greaseproof, barrier materials are required.Class 2 use.Class 2 material with kraft backing is for use in packages where the combined weight inside the barrier does not exceed 10 pounds. Class 2 material should be limited to use in bags whose inside length plus width does not exceed 42 inches. Class 2 materials should not be used in floating bag applications, in packaging operations under low temperature conditions below 32° F where fabrication or manipulation of the material is required, or where a double seam junction is fabricated. To prevent cracking and pin holing, packages fabricated from this material should not be handled at temperatures below 32° F.Bag Types:

Class 1 material with plastic non-woven backing is intended to be used in all packaging applications where heat-sealable, water vapor-proof, greaseproof, barrier materials are required.

Class 2 material with kraft backing is for use in packages where the combined weight inside the barrier does not exceed 10 pounds. Class 2 material should be limited to use in bags whose inside length plus width does not exceed 42 inches. Class 2 materials should not be used in floating bag applications, in packaging operations under low temperature conditions below 32° F where fabrication or manipulation of the material is required, or where a double seam junction is fabricated. To prevent cracking and pin holing, packages fabricated from this material should not be handled at temperatures below 32° F.

Military Packaging Barrier Rolls Bags Pouches Tubing

MIL-PRF-81705D Flexible Barrier ESD Foil Bagging Material

The barrier materials covered by this specification are intended for use in specialized military methods of preservation. The combination of all performance characteristics of MIL-PRF-81705; electromagnetic interference attentuation; electrostatic shielding, static shielding; static decay; water vapor transmission rate; surface resistivity waterproof-ness; transparency; marking abrasion resistance; thickness; aging; seam strength and fabrication; breaking strength; puncture; blocking and curl resistance; contact corrosivity; delamination; water resistance of marking, provides the necessary requirements for protection from exposure to the extremes of the navy/naval aviation environment. Navy/naval aviation items are exposed to high moisture, high salt concentration, transfer at sea, rough handling, and minimal storage conditions. There are no commercial equivalents that meet the physical, mechanical, and corrosion requirements necessary to protect material that is exposed to the operational naval aviation environment. Specifically, Specialized Method of Preservation, GX of MIL-STD-2073-1C use MIL-PRF-81705 as the premier source of barrier materials that provide water vapor proof and electrostatic discharge protection for applicable items encountering the above conditions. MIL-PRF-81705 provides the building blocks for applying Electrostatic ESD Discharge Protective techniques approved under MIL-STD-2073-1C.

Types:

Type I material is intended for use for water vapor proof, electrostatic and electromagnetic protection of microcircuits and semiconductor devices, such as diodes, field effect transistors, and sensitive resistors.

Type II material is intended for use where transparency and static dissipation is required and contact with oil or grease is not contemplated.

Type III material is intended for use where a transparent, waterproof, electrostatic-protective and electrostatic field protective barrier is required.

Mil-DTL-117H Mil Spec Military Bag Packaging Fabrication

Bags covered by this specification are intended for use in specialized military methods of preservation. The barrier materials, from which these bags are constructed of, are all approved by the military and provided the necessary requirements for protection from exposure to extremes of the navy / naval aviation environment. There are no commercial equivalents that meet the requirements necessary to protect material that is exposed to the operational naval aviation environment. Specifically, methods of preservation 31, 32, 33, 41, 42, 51, and 52 utilize these bags in order to provide the specialized military preservation required by MIL-STD-2073-1

Class A and H Bags are intended for preserving electrostatic discharge sensitive items.

Class B bags are intended for preserving items that require waterproof protection as specified in MIL-STD-2073-1, Method 31 and Method 32

Class C bags are intended for preserving items that require greaseproof protection in addition to waterproof protection as specified in MIL-STD-2073-1. Method 33.

Class E bags are intended for preserving items that require water vapor proof, waterproof, and greaseproof protection as specified in MIL-STD-2073-1, Method 41, 42, 51, and 52.

Class F bags are intended for preserving electrostatic discharge sensitive items. They also provide electromagnetic interference and electrostatic shielding protection. Additionally, these bags provide the water vapor proof protection as specified in MIL-STD-2073-1, Method 41, and Method 51.

Mil-PRF-22191D Flexible Milspec Barrier Packing Material

The barrier materials covered by this specification are intended for use in specialized military methods of preservation. The combination of all performance characteristics of MIL-PRF-131; seam strength and fabrication; water vapor transmission rate; breaking strength; puncture, blocking and curl resistance; contact corrosivity; delamination; and water resistance of markings provide the necessary requirements for protection from exposure to the extremes of the navy/naval aviation environment. Navy/naval aviation items are exposed to high moisture, high salt concentration, transfer at sea, rough handling, and minimal storage conditions. There are no commercial equivalents that meet the physical, mechanical and corrosion requirements necessary to protect material that is exposed to the operational naval aviation environment. Specifically, Methods 41, 42, 43, 51, 52, and 53 of MIL-STD-2073-1C use MIL-PRF-131 as the premier source of barrier materials that provide water vaporproof (and water vapor proof with desiccant) protection for applicable items encountering the above conditions. MIL-PRF-131 provides the building blocks for applying specialized military preservation techniques approved under MIL-STD-2073-1C.

Type I use. Type I materials is intended to be used in all packaging applications where water vapor proof, greaseproof barrier materials are required. Type II use.Type II material is intended to be used in all packaging applications where waterproof, greaseproof barrier materials are required.Type III use.Type III material is intended to be used in all packaging applications where waterproof barrier materials are required.Types:

Type I materials is intended to be used in all packaging applications where water vapor proof, greaseproof barrier materials are required.

Type II material is intended to be used in all packaging applications where waterproof, greaseproof barrier materials are required.

Type III material is intended to be used in all packaging applications where waterproof barrier materials are required.

Mil-PRF-121G Flexible Barrier Packaging Material

The barrier materials covered by this specification are intended for use in specialized military methods of preservation. The combination of all performance characteristics of MIL-PRF-121; flexibility, water proof-ness; contact, corrosivitiy; grease proofness; seam strength and fabrication; puncture, bursting, aging, blocking, and curl resistance; delamination; water resistance of marking provide the necessary requirements for protection from exposure to the extremes of the navy/naval aviation environment. Naval/naval aviation items are exposed to high moisture, high salt concentration, transfer at sea, rough handling, and minimal storage conditions. There are no commercial equivalents that meet the physical, mechanical, and corrosion requirements necessary to protect material that is exposed to the operational naval aviation environment. Specifically, MIL-STD-2073-1, Methods of Preservation 20 and 33, use MIL-PRF-121 as a primary source of barrier materials that provide waterproof and greaseproof protection for applicable items encountering the above conditions. MIL-PRF-121 provides one of the building blocks for applying specialized military preservation techniques approved under MIL-STD-2073-1.

Packaging Method

MIL-DTL-117H-Type I-Class E-Style I

MIL-B-117G-Type IV-Class E-Style I

MIL-DTL-117H-Type II-Class E-Style I

MIL-DTL-117H-Type II-Class C-Style I

MIL-DTL-117H-Type III-Class C-Style I

MIL-DTL-117H-Type II-Class C-Style II

MIL-DTL-117H-Type I-Class E-Style II

MIL-DTL-117H-Type III-Class B-Style II

MIL-DTL-117H-Type I-Class F-Style I

Material Specifications

Material Specifications

MIL-PRF-131K-Class I (Foil or Tyvek)

MIL-B-131K-Class III (Scrim Foil)

MIL-PRF-131K-Class II (Paper Foil)

MIL-PRF-121G-Type I (Poly Kraft)

MIL-PRF-121G-Type II (Poly Kraft)

MIL-PRF-22191-E-Type II (Poly Mylar)

MIL-PRF-22191-E-Type I (Aclar Poly)

MIL-PRF-22191-E-Type III (Polyethylene)

MIL-PRF-81705-E-Type I

(ESD/EMI Opaque Static Shielding)

Film Foil Tyvek Scrim

Barrier Materials Roll Stock

**ALL MATERIAL CAN BE SLIT TO ORDER**

Bags Transparent Film (MIL-PRF-22191E Type II)

Electrostatic Free Barrier Bags (MIL-PRF-81705E Type I)

(For packaging missiles, explosives power and electro sensitive devices, micro circuits, semi-conductors, thin film resistors and associates airborne component)

Film Foil MIL-PRF-131 CL I

For Kraft foil Bags Mil PRF-131-CL I

Poly Kraft MIL-PRF-121G TY II GR A CL I

Mil-PRF-121G Mil-spec packaging bag sheets rolls

MIL PRF-131-J CL 1 & II

Moisture protection, vapor proof, corrosion resistance, highly tensile/high puncture strength Scrim Moisture protection, vapor proof, heat sealable, corrosion resistance.

Film Foil MIL PRF-131-K CL1 Type I

36 x 200yds

48 x 200yds

Tyvek Foil Dupont Polyolefin

MIL PRF-131-K CL I Type I

36 x 200yds

48 x 200yds

Scrim Foil

MIL PRF 131H, CL III

36 x 200yds

48 x 200yds